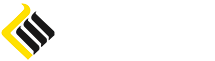

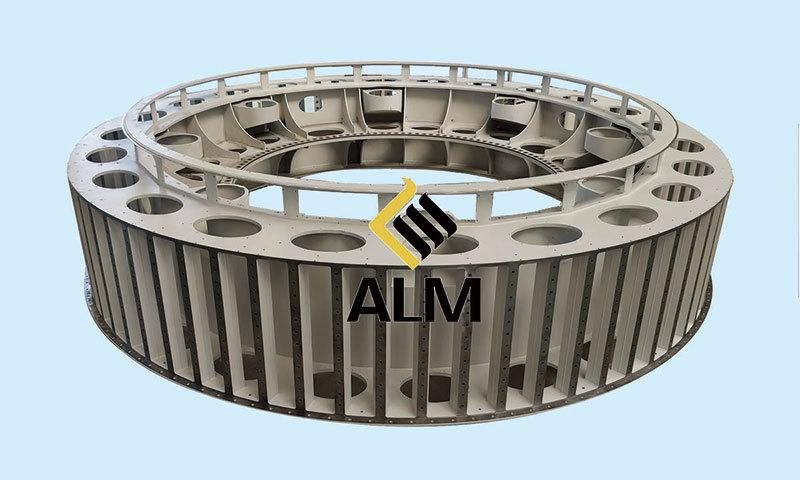

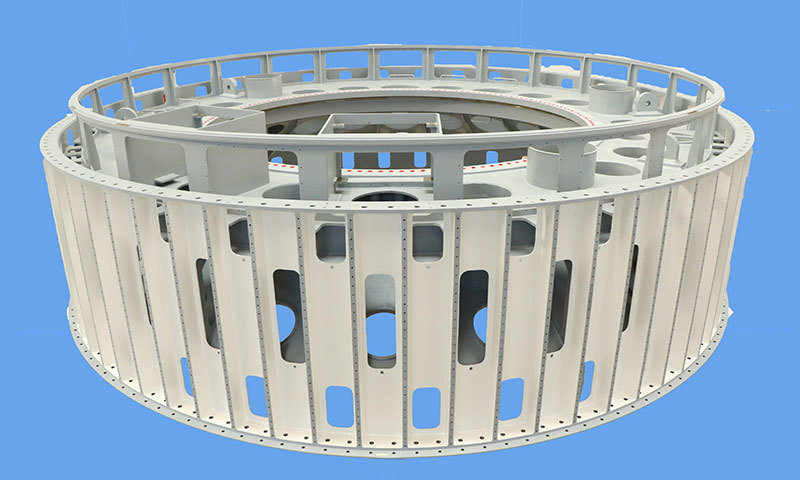

1. During the riveting process of the rotor bracket, in order to ensure the thickness of the magnetic yoke after processing, the process of processing the magnetic yoke in combination with the front rotor core is adopted. At present, the overall bonding process of the 1.5mw, 2.0mw and 2.5mw rotor brackets adopts the process measures of machining the rotor core and pairing with the magnetic yoke, which effectively ensures the uniformity of the roundness of the yoke after welding and the wall thickness after processing.

VIEW MORE

1. During the riveting process of the rotor bracket, in order to ensure the thickness of the magnetic yoke after processing, the process of processing the magnetic yoke in combination with the front rotor core is adopted. At present, the overall bonding process of the 1.5mw, 2.0mw and 2.5mw rotor brackets adopts the process measures of machining the rotor core and pairing with the magnetic yoke, which effectively ensures the uniformity of the roundness of the yoke after welding and the wall thickness after processing.

VIEW MORE

1. During the riveting process of the rotor bracket, in order to ensure the thickness of the magnetic yoke after processing, the process of processing the magnetic yoke in combination with the front rotor core is adopted. At present, the overall bonding process of the 1.5mw, 2.0mw and 2.5mw rotor brackets adopts the process measures of machining the rotor core and pairing with the magnetic yoke, which effectively ensures the uniformity of the roundness of the yoke after welding and the wall thickness after processing.

VIEW MORE