GROUP OVERVIEW

ABOUT US

Shandong Longma Holding Group Co., Ltd. (referred to as Longma Holding) was founded in 2003. The company focuses on the fields of wind power equipment, auto parts, mechanical equipment, cranes, and pressure vessels. It has now developed into a large wind power host product manufacturer in China. Over the years, it has been committed to scientific and technological innovation, quality control, and core technology breakthroughs in the industry-leading position. The company has successively been awarded "National High-tech Enterprise", "Provincial Enterprise Technology Center", "China Foundry Industry Credit Rating AAA Unit", "National Class III Pressure Vessel Manufacturing License", "I and II Pressure Vessel Design Certificate" , "GC2-level pressure pipeline installation certificate", "A-level lifting machinery, tower crane manufacturing, installation, renovation and maintenance certificate".

Founded in 2003

Professional skill worker

The largest single piece of castable ductile iron castings

At present, wind power castings cover 1.5-DX (above 10MW) products

Founded in 2003

Professional skill worker

The largest single piece of castable ductile iron castings

At present, wind power castings cover 1.5-DX (above 10MW) products

PRODUCTS

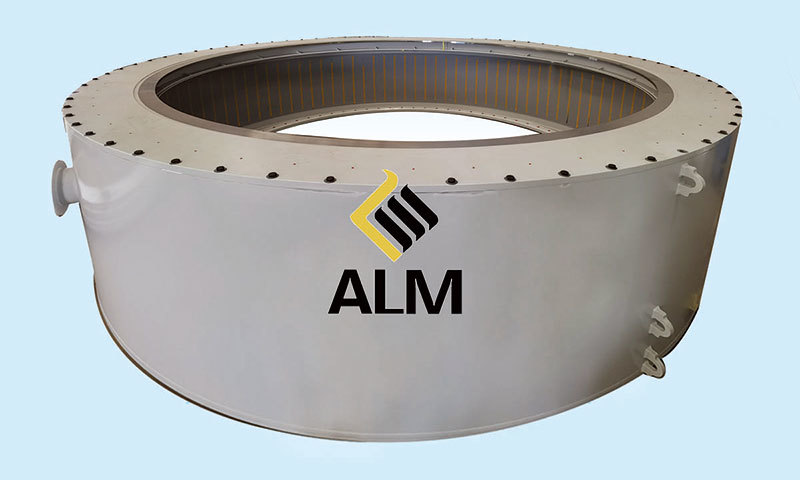

Main business of fan stator and rotor bracket structure, structural accessories, engine room base, hoisting machinery, pressure vessel, construction machinery accessories, electrical equipment, etc.

QE Double Girder Double Trolley Overhead Crane

Shandong Longma Wind Energy Equipment Co., Ltd. is mainly engaged in the business of fan stator and rotor support structures, structural accessories, engine room bases, lifting machinery, pressure vessels, construction machinery accessories, electrical equipment and other businesses. Large-scale manufacturing enterprises with production capacity.

QD600-260t-Double Girder Overhead Crane

Shandong Longma Wind Energy Equipment Co., Ltd. is mainly engaged in the business of fan stator and rotor support structures, structural accessories, engine room bases, lifting machinery, pressure vessels, construction machinery accessories, electrical equipment and other businesses. Large-scale manufacturing enterprises with production capacity.

900t-Shipbuilding Gantry Crane

Shandong Longma Wind Energy Equipment Co., Ltd. is mainly engaged in the business of fan stator and rotor support structures, structural accessories, engine room bases, lifting machinery, pressure vessels, construction machinery accessories, electrical equipment and other businesses. Large-scale manufacturing enterprises with production capacity.

Shandong Longma Wind Energy Equipment Co., Ltd. is mainly engaged in the business of fan stator and rotor support structures, structural accessories, engine room bases, lifting machinery, pressure vessels, construction machinery accessories, electrical equipment and other businesses. Large-scale manufacturing enterprises with production capacity.

Shandong Longma Wind Energy Equipment Co., Ltd. is mainly engaged in the business of fan stator and rotor support structures, structural accessories, engine room bases, lifting machinery, pressure vessels, construction machinery accessories, electrical equipment and other businesses. Large-scale manufacturing enterprises with production capacity.

According to the structural characteristics of the product, submerged arc welding is widely used in annular welds and butt welds of medium and heavy plates. The welding seam is uniform in shape, good in appearance, and has a high NDT qualification rate. It also improves welding automation and reduces labor intensity. Rotor bracket submerged arc welding The utilization rate can reach 75~85%.

According to the structural characteristics of the product, submerged arc welding is widely used in annular welds and butt welds of medium and heavy plates. The welding seam is uniform in shape, good in appearance, and has a high NDT qualification rate. It also improves welding automation and reduces labor intensity. Rotor bracket submerged arc welding The utilization rate can reach 75~85%.

1. During the riveting process of the rotor bracket, in order to ensure the thickness of the magnetic yoke after processing, the process of processing the magnetic yoke in combination with the front rotor core is adopted. At present, the overall bonding process of the 1.5mw, 2.0mw and 2.5mw rotor brackets adopts the process measures of machining the rotor core and pairing with the magnetic yoke, which effectively ensures the uniformity of the roundness of the yoke after welding and the wall thickness after processing.

CHOOSE US

OUR ADVANTAGE

Shandong Longma Wind Energy Equipment Co., Ltd. was founded in 2002. It is a large-scale manufacturing enterprise with the production capacity of welding, processing, painting and installation.

PARTNER

The company adheres to the vision of "serving the world from China", and follows the historical mission of "leading the direction and creating the future". Under the background of Made in China 2025, the company grasps the world's cutting-edge technology and industrial development direction, based on the existing industrial foundation, and concentrates on development. Strengthen the equipment manufacturing industry, ensure a leading position in high-end intelligent manufacturing, and provide strong support for industrial development.

CRRC

ENVISION

Dongfang Electric

Shanghai Electric

XEMC

SINOHYDRO

Daikin heavy industry

VESTAS

Shengu group

HITACHI

XCMG

Goldwind Technology

NEWS

Grasp the world's cutting-edge technologies and industrial development directions, base on the existing industrial foundation, and concentrate on developing and expanding the equipment manufacturing industry

08

/

11

NEWS

08

/

11

NEWS